Industry-Leading CNC Machining (Communities - Services Offered)

CANetAds > Communities > Services Offered

Item ID 4259218 in Category: Communities - Services Offered

Industry-Leading CNC Machining | |

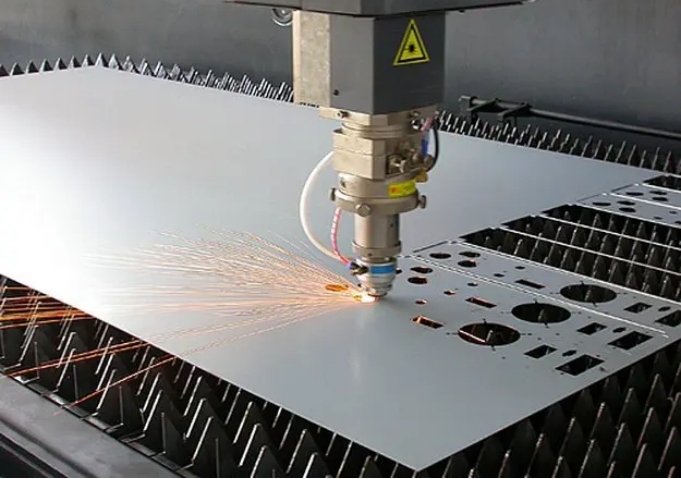

Precision Manufacturing Solutions for Modern Industries Manufacturing needs vary widely across industries, but the need for speed, reliability, and quality remains constant. The industry services described on the page offer CNC machining, sheet metal fabrication, and injection moulding tailored to six major sectors: Aerospace, Automotive, Industrial, Electronics, Medical, and Robotics. Each sector demands specific tolerances, materials, and turnaround speeds. The value of this service lies in providing a flexible manufacturing model—whether you need five parts or five thousand. Industry Applications 1. Aerospace This sector demands high-strength materials and tight tolerances. Machined parts, sheet-metal components, and specialised alloys are critical in aerospace structures, brackets, and housings. Repeatability and traceability are essential here. 2. Automotive In the automotive space, there’s a mix of mass production and rapid development. Injection moulded plastics, CNC-machined components, and metal fabrications are used in interiors, under-the-hood components, and prototype testing. Consistency and short lead times matter. 3. Industrial For equipment and infrastructure projects, custom brackets, plates, housings, and machine parts are common. These often involve sheet metal work, turning, milling, or welding. The focus is on durability, fit, and cost efficiency. 4. Electronics Electronics applications benefit from small, precision-machined parts or injection moulded housings. Plastic components require a clean finish and tight design repeatability, while metal parts may demand grounding features or thermal properties. 5. Medical Medical components must be clean, biocompatible, and manufactured to strict standards. CNC-machined metal parts or moulded plastic casings for diagnostic equipment are typical. Tolerances and surface finishes are critical. 6. Robotics Robotic systems rely on a combination of metal frames, plastic covers, sensor housings, and precision-machined joints. Rapid prototyping is common, but production-grade durability is still required. A hybrid of fabrication and machining is often used. Why This Matters to You Manufacturing for industry is rarely one-size-fits-all. If you’re building products or components in any of the above sectors, you need suppliers who understand those specific constraints. This service provides: Access to over 75 types of materials for metals, plastics, and rubber Production methods tuned for short-run or volume batches Support from prototype to final production Tolerance and finish control suitable for regulated or performance-critical industries Having multiple production methods—like CNC machining, injection moulding, and sheet-metal fabrication—under one roof reduces friction and risk between design and delivery. Final Considerations Choose processes that match your design’s volume and material requirements. Consider regulatory or finish needs early, especially for medical or aerospace. Leverage design-for-manufacture principles to cut lead times and lower cost. Build a long-term relationship with suppliers who can scale with your growth. This industry offering provides a practical, modular approach to modern manufacturing—especially when speed, variety, and precision are essential. Whether you're refining a prototype or scaling into full production, these services align well with industry needs.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target Prov.: British Columbia Target City : Greater Vancouver Last Update : Oct 24, 2025 1:23 AM Number of Views: 23 | Item Owner : jems Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

CANetAds > Communities > Services Offered

© 2025 CANetAds.com

USNetAds.com | GetJob.us | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-10-25 (0.434 sec)