High Quality Production Services Greater Vancouver (Communities - Services Offered)

CANetAds > Communities > Services Offered

Item ID 4259184 in Category: Communities - Services Offered

High Quality Production Services Greater Vancouver | |

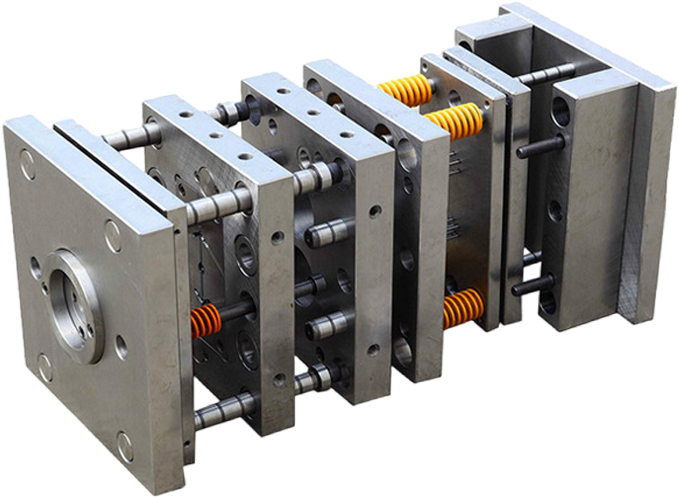

The “Production” page presents a manufacturing service offering that moves projects beyond prototype stage into full‑scale manufacturing. The focus is on repeatable, reliable production runs of parts—whether they are metal, plastic, or rubber—and delivering consistent quality at competitive cost. Naxtry +1 Scope & Capabilities This production offering covers a range of manufacturing processes: CNC machining (milling, turning) for metal and plastic parts. Naxtry +1 Sheet‑metal fabrication (laser cutting, water‑jet cutting, bending, welding and assembly) for enclosures, brackets and structural components. Naxtry +1 Injection moulding for plastics and rubber components, including tool‑making and production runs. Naxtry Post‑processing services such as surface finishing, plating, welding and assembly. Naxtry +1 Materials & Industry Coverage The service emphasises a broad materials‑portfolio: hundreds of metals, plastics and elastomers are supported. This allows part designers and engineers to choose materials that meet mechanical, thermal or chemical performance requirements. Naxtry +1 Industries served include automotive, aerospace, electronics, medical and industrial equipment. This diversity suggests the production workflow can handle everything from delicate precision parts to larger structural components. Naxtry +1 Why Production Matters to You If you’ve moved past the prototype phase and need to manufacture parts in quantity, the production service offers key benefits: Repeatability: Processes and quality controls tuned for production ensure uniform parts across batches. Scale‑readiness: Transitioning from prototype to volume production is smoother because the same manufacturing engine supports both. Cost‑efficiency: With tooling, set‑up and process optimisation aligned with production runs, the cost‑per‑part becomes more manageable. Lead‑time responsiveness: While prototypes emphasise speed, production emphasises consistency and delivery reliability—so you can have confidence in schedule. Important Considerations Tooling and setup cost: Production runs often require more tooling, fixtures or dedicated setup. The per‑part cost drops once volume is achieved, but initial investment must be weighed against quantity. Design for manufacture: Before moving to production, part design should be verified for tooling, tolerances, surface finish, material behaviour, lifecycle and assembly. Quality control and inspection: Production parts must meet tolerances, material specs and performance criteria — so quality systems must be in place. Sourcing and supply‑chain readiness: Materials, finishing processes and logistics need coordination to maintain production flow without delays. Volume vs method choice: For very high volumes the economics may shift (e.g., stamping or custom tooling); production services here seem well‑suited for small‑to‑medium runs across diverse processes. How to Use This Service If you’re preparing for production, you should: Finalise your part design, specify materials, tolerances and finishes. Align with the manufacturer on expected volumes, turnaround, inspection and delivery schedule. Confirm tooling, setup and process‑capability (does the machine/process exist in the facility for your part size/material?). Negotiate cost‑structure: per‑part, setup, tooling amortisation, perhaps re‑runs or failure allowances. Plan for finishing and assembly — production parts often require packaging, labelling or further processing before they hit your product line. In summary: this “Production” page presents a manufacturing service equipped for ramping from prototypes into full production with multiple processes, materials and finish options. If you are ready to move from concept or early runs into regular part manufacturing, this offering looks like a solid match—provided the volumes, design and budget align appropriately.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target Prov.: British Columbia Target City : Greater Vancouver Last Update : Oct 24, 2025 12:42 AM Number of Views: 29 | Item Owner : jems Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

CANetAds > Communities > Services Offered

© 2025 CANetAds.com

USNetAds.com | GetJob.us | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-10-25 (0.465 sec)