Sheet Metal Fabrication Service Greater Vancouver (Communities - Services Offered)

CANetAds > Communities > Services Offered

Item ID 4259176 in Category: Communities - Services Offered

Sheet Metal Fabrication Service Greater Vancouver | |

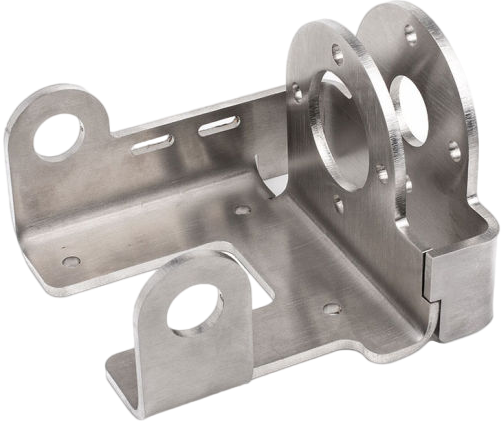

Sheet metal fabrication is a manufacturing process that transforms flat sheets of metal into parts and assemblies through cutting, bending, forming, joining and finishing. The service described covers the full workflow from prototype to on‑demand production, offering precision, material variety and efficient turnaround. Naxtry Capabilities & Key Processes The service offers several core capabilities: Laser cutting: Using CO₂ and fibre laser cutters to accurately cut sheet material with minimal heat distortion. Naxtry Water‑jet cutting: For thicker or heat‑sensitive materials, 3‑axis and 5‑axis water‑jet cutting is provided. Naxtry Bending and forming: Hydraulic CNC press‑brakes and servo‑electric CNC back‑brakes shape parts into U, V or channel profiles from flat sheet. Naxtry Assembly & joining: After individual parts are made, they can be welded, riveted, or otherwise joined into assemblies. Naxtry Finishing: Surface treatments like powder‑coating, paint, anodising, plating or sand‑blasting are offered to enhance durability or appearance. Naxtry This end‑to‑end process means you can move from a flat sheet design to a finished part or housing without switching suppliers. Materials & Options A wide array of materials is supported. For example: Aluminium alloys (6061, 7075, 5052) for lightweight applications. Naxtry Copper (C101, C110) for high ductility and conductivity. Naxtry Stainless steels (304, 316) for corrosion resistance and durability. Naxtry Mild steel (AISI 1018, A36) as a cost‑effective general‑purpose option. Naxtry Selecting the right material informs cutting method, bend radii, and surface finish—so early material discussion is a benefit. Advantages for the User Precision and consistency: The use of advanced CNC equipment and refined workflows means tight tolerances and repeatable quality. Naxtry Speed from prototype to production: The service is presented as suitable for one‑off prototypes as well as scaled production runs, helping bridge design and manufacturing. Naxtry Cost competitiveness: By combining efficient processes and direct manufacturing, the service targets competitive pricing compared to traditional fabrication paths. Naxtry Tailored finishing and assembly: Post‑fabrication options mean that not only are parts made, but they arrive closer to installation readiness. How to Make It Work For You If you are designing a sheet metal component, here are some key points: Provide a good CAD file with clear outlines, bend lines, and assembly references. Choose the material that matches environment and mechanical needs (weight, corrosion, strength). Account for manufacturing realities: bend radius, minimum feature size, welding/joining clearances. Clarify surface finish or assembly needs early—these affect lead time and cost. Use the fabricator’s capabilities (cutting size, bending capacity, join methods) to align your part design with realistic process limits. Things to Watch Very large bends, deep drawn shapes or ultra‑thin materials might need special tooling or alternative methods. Surface‑sensitive parts (for aesthetics or finish) may require extra process steps or inspection. While the service supports scaled volume, for extremely high volumes stamping might still offer lower cost per part—so balance part count vs method. In summary: the sheet metal fabrication service covers the full path from raw sheet metal to formed, joined and finished parts. If you have a design that requires metal enclosures, brackets, frames or assemblies and you want a streamlined manufacturing path, this offering is well‑suited.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target Prov.: British Columbia Target City : Greater Vancouver Last Update : Oct 24, 2025 12:36 AM Number of Views: 20 | Item Owner : jems Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

CANetAds > Communities > Services Offered

© 2025 CANetAds.com

USNetAds.com | GetJob.us | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-10-25 (0.391 sec)