CNC Turning Service Greater Vancouver (Communities - Services Offered)

CANetAds > Communities > Services Offered

Item ID 4259167 in Category: Communities - Services Offered

CNC Turning Service Greater Vancouver | |

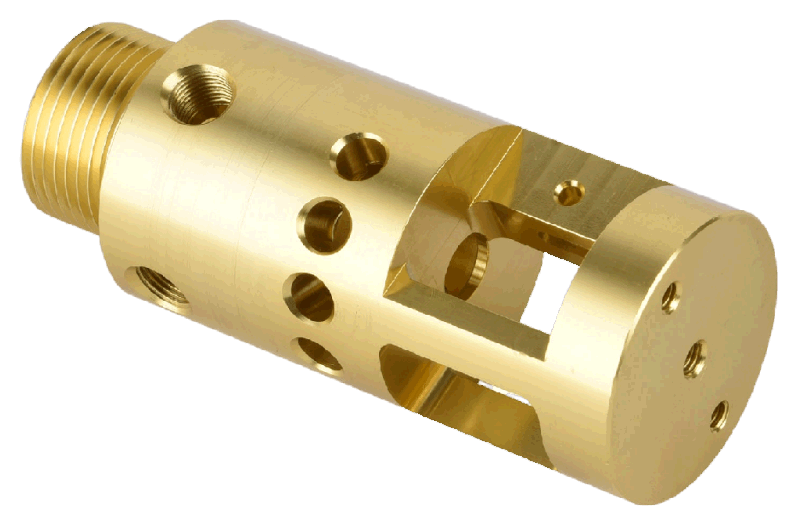

CNC turning is a manufacturing process where a workpiece rotates around a fixed axis while a cutting tool removes material to create cylindrical shapes, shafts, threaded features, internal bores and other rotational geometries. On the page you linked, this service is described as part of the broader CNC machining offering, where both milling and turning are provided for prototyping and production. Naxtry +1 Capabilities & Processes The turning service covers: 2‑axis turning: Traditional lathe operations where the workpiece rotates and a tool moves in two axes (often X and Z) to cut external / internal features. Naxtry Multi‑axis or bar feed turning: More advanced setups that may include live tooling, turrets, sub‑spindles, and can produce complex parts with milling or drilling features without transferring to a separate machine. While the page does not list every machine spec, it references “multi‑axis turning” as one of the capabilities. Naxtry Size limits and tolerances: The page states, for turning parts, maximum dimensions such as ‘D 50 x 60 in (1270 x 1524 mm)’ for 2‑axis turning, and similarly for multi‑axis machine setups. Naxtry Tolerances of ±0.005 in (±0.127 mm) are standard; tighter tolerances up to ±0.0005 in (≈0.0127 mm) may be available with customer specification. Naxtry Material Options & Versatility The turning service supports a wide variety of materials: typical metals (aluminium, stainless steels, tool and alloy steels, titanium, Inconel) and plastics (ABS, POM, nylon, PC, etc). Naxtry +1 Because the workpiece rotates and tools remove material, turning is very efficient for cylindrical parts, symmetric features, and high‑volume runs with consistent quality. Cost & Lead Time Advantages One of the appeals presented is rapid turnaround and cost competitiveness. The service is positioned for both rapid prototyping and production, meaning you can start with smaller batch runs and scale up. Naxtry Because machining centres (turning centres) are well suited for rotational geometries, cycle times tend to be lower compared with more complex setups, which can reduce cost per part, especially for volumes. Finishing & Value‑Added Services After turning, parts may require further operations: secondary machining (drilling, threading, milling), surface finishes (anodising, plating, black oxide, polishing), heat treatments or assembly. These finishing options ensure that the turned part meets functional, aesthetic or durability requirements. The broader machining service page lists surface finishing options available for machined parts. Naxtry Applications & Industries Turning is used heavily in industries where parts have rotational symmetry: shafts, spindles, bolts, housings, pulleys, bushings, and more. The capability to handle wide material choice, tight tolerances and fast turnaround makes it relevant in sectors like automotive, aerospace, industrial equipment, robotics and electronics. The page lists those industries for the CNC machining offering which includes turning. Naxtry Why It Matters for You If you have a part that is predominantly cylindrical or axisymmetric, CNC turning is often the most efficient method. Benefits include: High repeatability and consistent accuracy. Ability to machine both metal and plastic materials. Efficient material removal and cost savings for volume parts. Smooth pathway from prototype to production — you can test with a few pieces, then ramp up without changing manufacturing method. Key Considerations Even though turning is efficient, design should consider tool access, part geometry (e.g., deep bores, undercuts) and fixture/setup constraints. Material selection still matters: some alloys are more difficult to turn (require slower speeds, special tooling) which affects cost. Finishes and tolerances need to be specified upfront. Achieving very tight tolerance or special surface finish adds cost/time. For extremely complex geometries (non‑rotational features), turning alone may not suffice — you may need hybrid machining or separate milling. In summary: this CNC turning service offers a robust and flexible solution for producing machined parts with rotational geometries — from prototype to production runs — with broad material support, strong competency in tolerances and finishing, and a cost/time efficient pathway. If you need precise turned components made from metal or plastic and want consistent quality and pace, this offering aligns well.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target Prov.: All Provinces Target City : Greater Vancouver Last Update : Oct 24, 2025 12:23 AM Number of Views: 24 | Item Owner : jems Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

CANetAds > Communities > Services Offered

© 2025 CANetAds.com

USNetAds.com | GetJob.us | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-10-25 (0.491 sec)