Plastic Injection Molding Service Greater Vancouver (Communities - Services Offered)

CANetAds > Communities > Services Offered

Item ID 4259158 in Category: Communities - Services Offered

Plastic Injection Molding Service Greater Vancouver | |

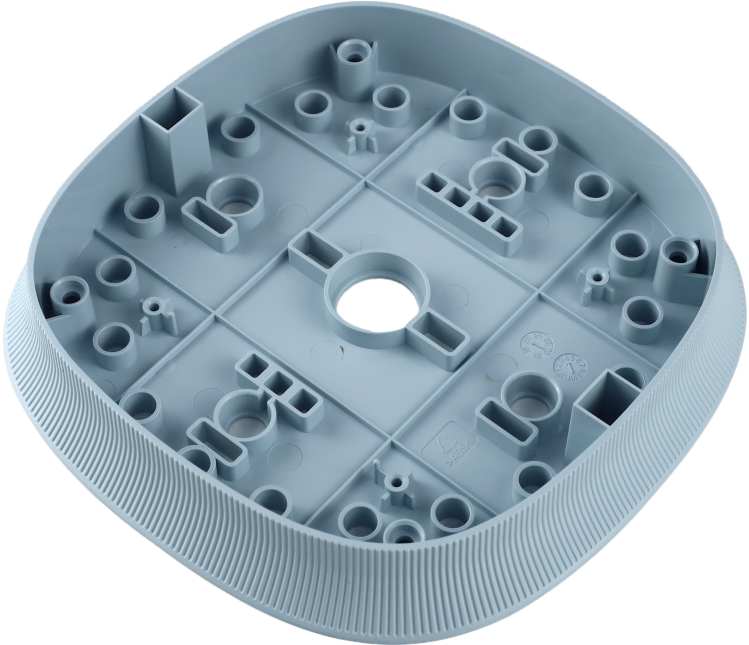

Plastic injection moulding is a manufacturing process where molten plastic is injected into a custom‑built mould tool, allowed to cool and solidify, and then ejected as a finished part. The service described on the page covers the full workflow for plastic injection—from mould engineering through production and finishing. Process & Workflow Design & Engineering: The process begins with assessing your part design for moulding suitability—looking at wall thicknesses, draft angles, gate locations, cooling channels, etc. Tooling (Mould Making): A mould is designed and fabricated (often steel or aluminium) tailored to your part geometry and anticipated run volume. Material Selection: A wide range of thermoplastic materials is available. The correct choice depends on strength, thermal/chemical resistance, cost, and intended application. Injection Moulding: Once the mould and material are ready, molten plastic is injected under pressure into the mould cavity. The part cools and solidifies, at which point it’s ejected. Quality Control & Finishing: After moulding, parts undergo inspection to confirm dimensional accuracy and consistency. Then finishing options such as surface texture, coating, painting, marking or assembly may be applied. Material Options The listing includes many commonly used thermoplastics such as: ABS (and ABS‑PC blends): good impact resistance, strength‑to‑weight ratio. Acetal (POM): high strength and stiffness with good wear resistance. Nylon (various grades): durable, lightweight, good chemical resistance. Polycarbonate (PC): high impact strength, transparency, and thermal stability. Polypropylene (PP), PET, HDPE/LDPE, PMMA, PEI, PPS, PEEK etc: each tailored for specific trade‑offs of cost, durability, heat/chemical resistance. This material breadth lets you target part performance (e.g., mechanical load, temperature) and cost. Cost, Lead Time & Volume An important point is the upfront tooling cost plus per‑part cost. The cost model includes: material cost + hourly rate × hours + one‑time mould/setup cost. The moulding service presents sample cost comparisons showing lower hourly rates and tooling costs than typical industry averages. Lead times can be fast (prototyping and production) and there is provision for low to moderate volumes. Equipment & Capabilities The moulding machines range in size (tonnage) to support various part sizes and volumes. Advanced machines ensure precision, repeatability and automated control. The service highlights capability to support complex parts with custom moulds, and finishing processes. Finishing & Value‑Added Services Moulded plastic parts may require post‑processing to meet final product specifications. Finishing options include: Laser marking for branding or identification. Texturing/graining of part surfaces via the mould tool. Coating, painting, or powder‑coat for appearance or protection. Polishing for high aesthetic finish. Ultrasonic welding or assembly for multi‑component parts or sub‑assemblies. Applications & Industries This service is applicable across many industries: consumer goods, electronics, automotive interiors/exteriors, packaging, industrial equipment, medical devices. The ability to mould a wide variety of plastics, customise surface finish, and handle prototyping through production makes it versatile. Why It Matters for You If you have a design that needs plastic parts molded in quantity, plastic injection moulding gives you: consistent part quality across large volumes; the ability to select materials matching mechanical/thermal/chemical needs; cost‑effective part cost at scale (once tooling amortised); finishing options that integrate into your product’s look or performance. Key Considerations Up‑front tooling cost can be significant—evaluate volume vs. cost. Design must be mould‑friendly: wall thickness uniformity, draft, tool access. Material choice must align with intended part use (load, temperature, environment). Finishing adds cost/time—plan early. For lower volumes or early prototypes, other methods (machining or additive) may be more economical until you scale. In summary: the plastic injection moulding service offers a full‑service solution from design through production and finishing, with broad material choice, fast turnaround, and cost‑effective production for the right volumes. It is well suited for creating durable, consistent plastic parts when you’ve moved past prototype and into repeat production.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target Prov.: British Columbia Target City : Greater Vancouver Last Update : Oct 24, 2025 12:15 AM Number of Views: 23 | Item Owner : jems Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

CANetAds > Communities > Services Offered

© 2025 CANetAds.com

USNetAds.com | GetJob.us | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-10-25 (0.381 sec)